As enthusiasts, many of us know that the presentation is everything. It doesn’t matter if you’re seeking trophies or accolades, if your ride doesn’t look great then it’s not going to stand out at a show or event. We love it when someone is in awe of our pride and joy, right? Sometimes being different is enough, other times you simply need that ‘wow’ factor to draw people in, and it gets them wanting to know more about your build.

For us, it’s about the bigger picture; having the most power isn’t always noticeable when the car is parked. We like the little details that often get overlooked by others. If you’re the kind of person that spends hours removing small parts from your engine just to put a fresh coat of paint on them, then you know what we’re talking about. We like to see that attention to detail, especially when it comes to engine components.

For us, it’s about the bigger picture; having the most power isn’t always noticeable when the car is parked. We like the little details that often get overlooked by others. If you’re the kind of person that spends hours removing small parts from your engine just to put a fresh coat of paint on them, then you know what we’re talking about. We like to see that attention to detail, especially when it comes to engine components.

In our last entry for Project Windstorm, we shared a unique tool that assisted us with removing the supercharger pulley. We acquired the tool from Metco Motorsports; created in 2000, they have been toying around with the Hellcat since they first appeared in 2015. We’re no stranger to the Hellcat; we got to play with one for a week in 2014. While the Hellcat had the most horsepower you could get from an American production car at that time, the old saying of “too much power isn’t enough” rang true for lots of Hellcat owners – and Rick Bejarano was one of those people.

We got to talk with Rick about his Pin Holding Tool and got some great advice and suggestions for removing the Hellcat pulley from our Redeye. As we got to talking, Rick shared some insights with us about other product offerings from Metco, and he shared some info about the pulleys that he manufactures for the Hellcat engines. His wife, Kristi, bought the first Hellcat sold in their town, but even before that, Rick – with some inside information about the Hellcat mill – began to develop parts even before Kristi took delivery of her 2015 Hellcat Challenger.

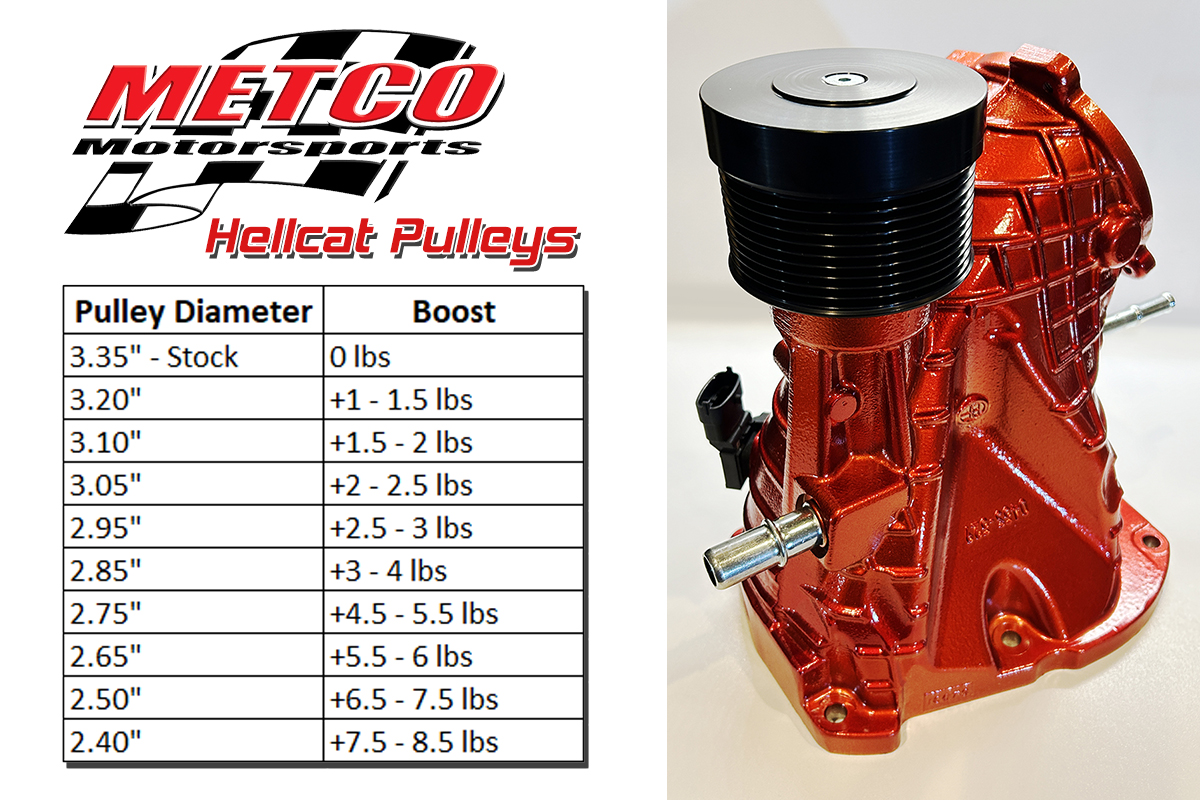

On the path to seeking more boost, one method is a smaller pulley – which will spin the supercharger a little faster through the entire rpm range. While some may have the “more power” notion imprinted on the brain, there are some things to consider about going to a smaller pulley size. The 797hp of the Hellcat Redeye is plenty for now, so we opted for Metco’s stock pulley size. They offer ten pulley sizes, ranging from 3.35″ stock, down to 2.40″ – which is good for adding roughly 7.5 – 8.5lbs of boost to the Redeye’s existing 14.5 psi.

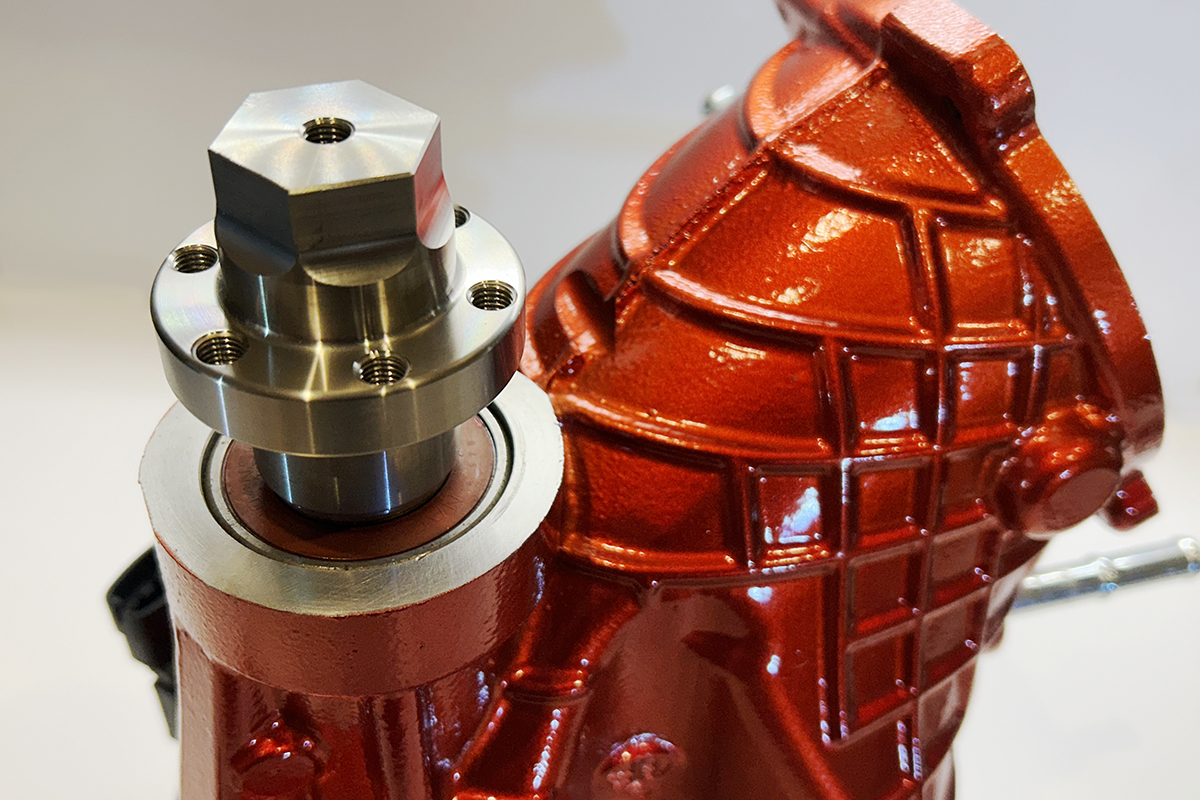

One thing we noticed about the Metco supercharger pulleys is the lack of a clutch-style mechanism that is present on the OE supercharger pulley; we asked Rick to tell us about that. “We investigated the option of manufacturing a clutched pulley like the OEM unit vs. offering a fixed pulley like we have done for previous supercharged applications,” Rick told us. “Immediately, concerns developed with the clutched pulley regarding the durability of this design. It is necessary to reduce the size and mass of the clutch mechanism to fit it inside a performance pulley size, and these smaller clutch components could not offer the durability of the original pulley.”

Rick tells us that the reason for the OEM to use a clutch-style pulley is to allow the supercharger to slow down at a different rate than when getting off the gas; it’s one of those features the OEM does to give the car better manners in stop-and-go traffic. We asked if the lack of a clutch-style pulley would cause any concerns, but he assured us that some belt slip is not detrimental to the entire system. “There is a tendency among installers to use belts that are too tight in the interest of eliminating belt slip, but belts that are too tight shorten the service life of every component they touch,” he told us. “Even the bearings in the supercharger snout can be a risk when belt tension is excessive.”

He assured us that some belt slip is necessary in a properly set up blower drive, and that the ‘chirp’ you might hear is when the belt allows the supercharger pulley to synch back up following abrupt changes in throttle position, such as accelerating hard, and then abruptly backing off on the gas. Having the proper belt tension is crucial to longevity, and Metco has compiled data on proper belt length for various pulley combinations that they’ll gladly share with customers. Since we’re using a stock-size pulley, there was one other question we had for Rick about pulley sizes.

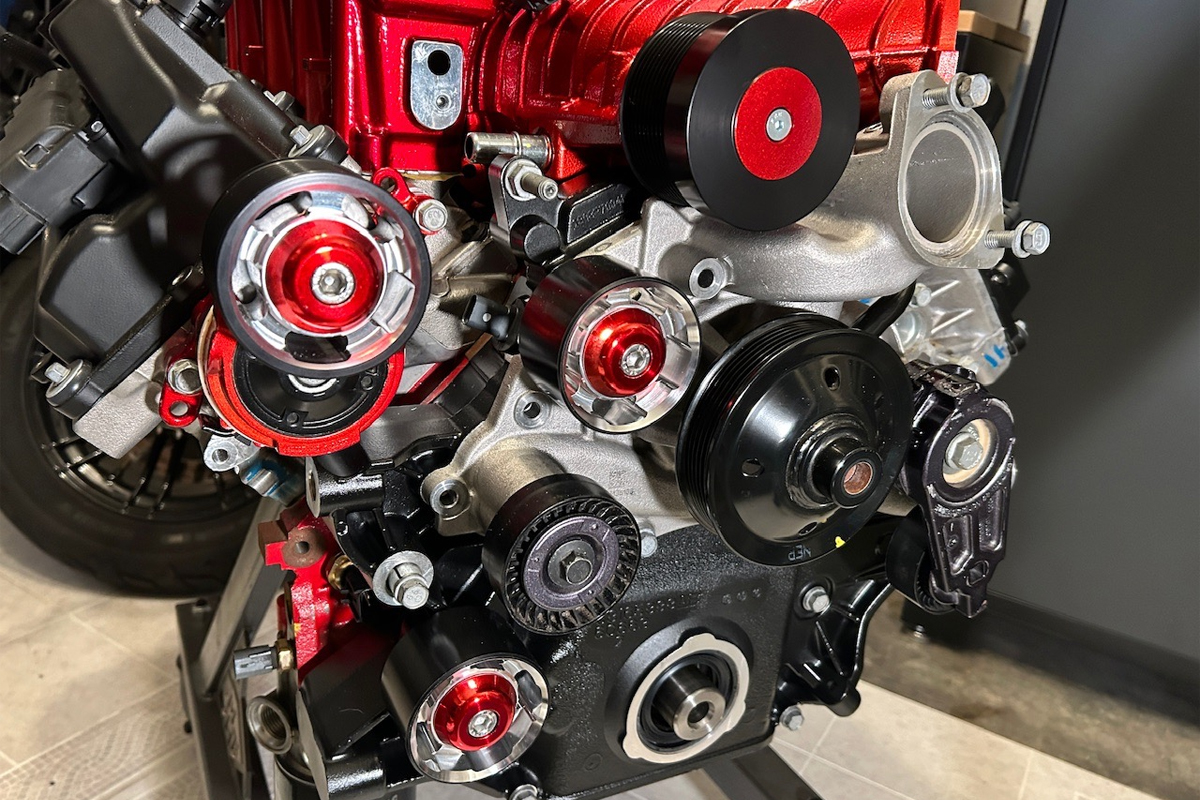

We noticed that the Metco idler and tensioner pulleys are slightly larger than the OE pulleys, and asked about the size difference. Rick said, “We designed our pulleys slightly larger than the originals for several reasons. One reason is that the 76mm size we use is a standard go-to size for many popular applications.” That made sense to us, why make multiple sizes when there’s a benefit to the ‘one size fits all’ approach. Rick continued, “Additionally, the slightly larger diameter of our pulley improves belt wrap slightly at all contact points. Also, our larger OD reduces speed at the pulley bearing for improved durability and longevity.”

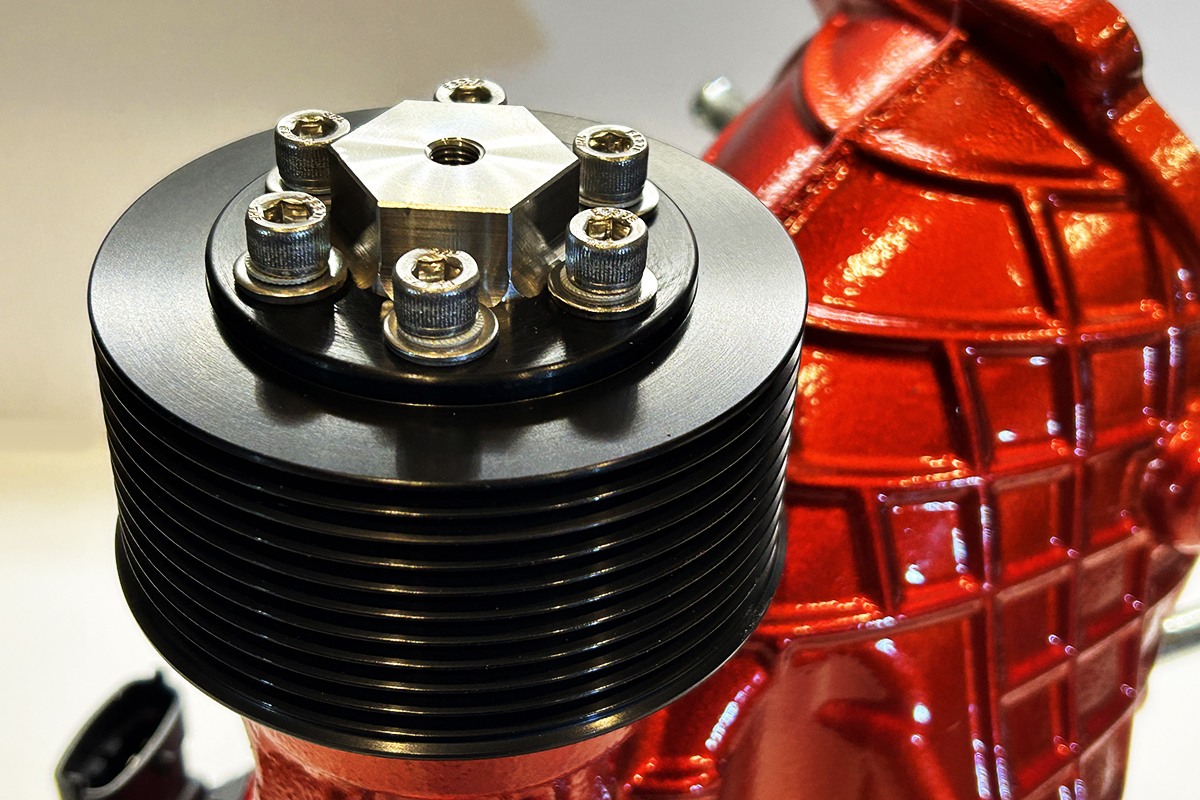

The pulleys are manufactured on one of six state-of-the-art CNC machines in Metco’s modest size shop in Anderson, South Carolina. They use a military-spec hardcoat anodizing on the pulleys that actually penetrates the aluminum and makes it significantly stronger. Rick said, “This finish is expensive, but it will literally last forever, only growing shinier as miles accumulate. This finish also provides the optimum surface for the belt to ride on, extending belt service life and reducing belt noise.”

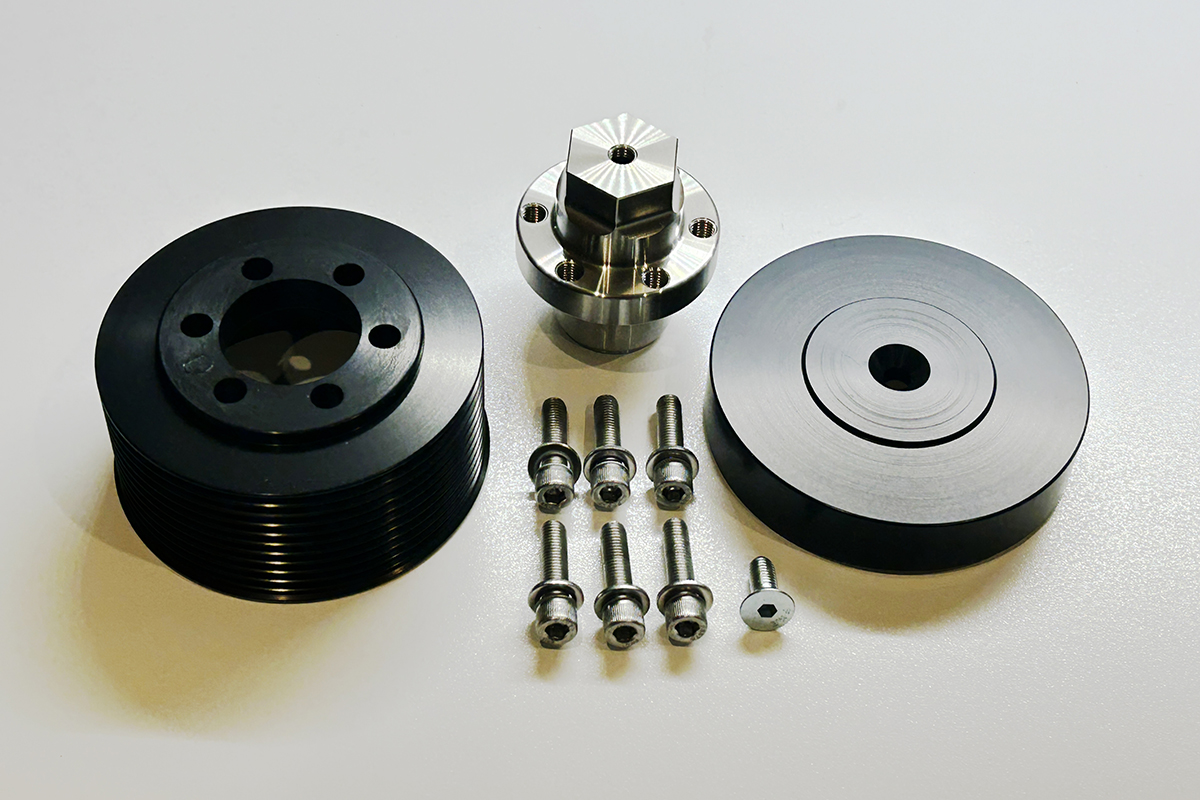

Making a pulley change with the Metco Motorsports pulley is a quick process: remove the center cover and the six bolts holding the pulley in place, and install the new one. It’s that simple.

Making a pulley change with the Metco Motorsports pulley is a quick process: remove the center cover and the six bolts holding the pulley in place, and install the new one. It’s that simple.

That left us with one final question for Rick, for now, and that is regarding the use of smaller supercharger pulleys: how much is too much, and which pulleys are ‘safe’ for a stock application? “This is a dangerous question to consider,” he told us, “because there are so many variables that affect the level of cylinder pressure resulting from a pulley change.” He explained further, “I’ve seen our 3.20” and also 3.10” pulleys used to safely replace the original 3.35” on a non-modified Hellcat. These changes have been dyno-tested and proven multiple times over the years, with air/fuel measured after the change in many instances. These pulley changes did not make as much power as they would have if made with the matching tune, but they did result in substantially more power.”

While this Hellcat Redeye is a first endeavor into a supercharged application, we realize that there’s a lot to learn about adding boost, and doing so without harming the engine. These days with PCMs that need calibration every time you make a change in horsepower, it’s become a far cry from the musclecar era when many of us went out and slapped a bigger carburetor on our small-block with its anemic 185 horsepower. Sure, the car didn’t run at its optimum without a good dyno tune, but that bigger carburetor only hurt our wallets at the gas pump – not our engines.

Playing around with boost on a computer-controlled mill requires much more of an education than you can get from turning a couple of adjustment screws with a screwdriver. We still have much to learn, and if you want to learn more about pulley sizes and adding boost, be sure to reach out to Metco Motorsports with your questions – some of its upgrades includes Ford’s Lightning, Mustang Cobra, and GT500, as well as Cadillac DTS-V and Chevy’s ZL1 Camaro and Z06 Corvette. They also manufacture suspension components, driveshaft safety loops, and lots of other parts for early musclecars.