Does an EFI system pay for itself? It’s been an age old question, and one that has taken a lot of people off the fence when it comes to converting to an EFI system. Decades ago, it wasn’t the greatest venture to steer away from carburetion on a classic musclecar; EFI conversions were difficult, they required a lot of knowledge and research, and they even required the ability to tune them – typically with a laptop computer. That last detail was usually enough to scare most people away.

But that was years ago, and like anything EFI systems have evolved. There are several companies out there who have improved their EFI system to the point where just about anyone with basic automotive knowledge and skills can install EFI. Many are pitched with the encouragement of “if you can install a carburetor, you can install EFI.”

You don’t see a yellow Polyhead 318 anywhere, being different is what it’s all about.

You don’t see a yellow Polyhead 318 anywhere, being different is what it’s all about.

Still, there was the cost factor that had most people staying with their carburetor. But there are some things to consider when you use the cost factor to determine whether a carburetor or an EFI system is best for your application. We are going to answer that question: Does an EFI system really pay for itself in the long run?

Cost Versus Function: Tuning Your Carburetor

When you look at the cost of an EFI system, which can run upwards of $1,500 or more, it seems pretty clear that a carburetor is going to be more affordable as well as easier to work with for the typical gearhead. For years we’ve been told that carburetors are ‘Ready to Run’ right out of the box: just install it, turn a couple screws and adjust your idle, and away you go. But is that really accurate?

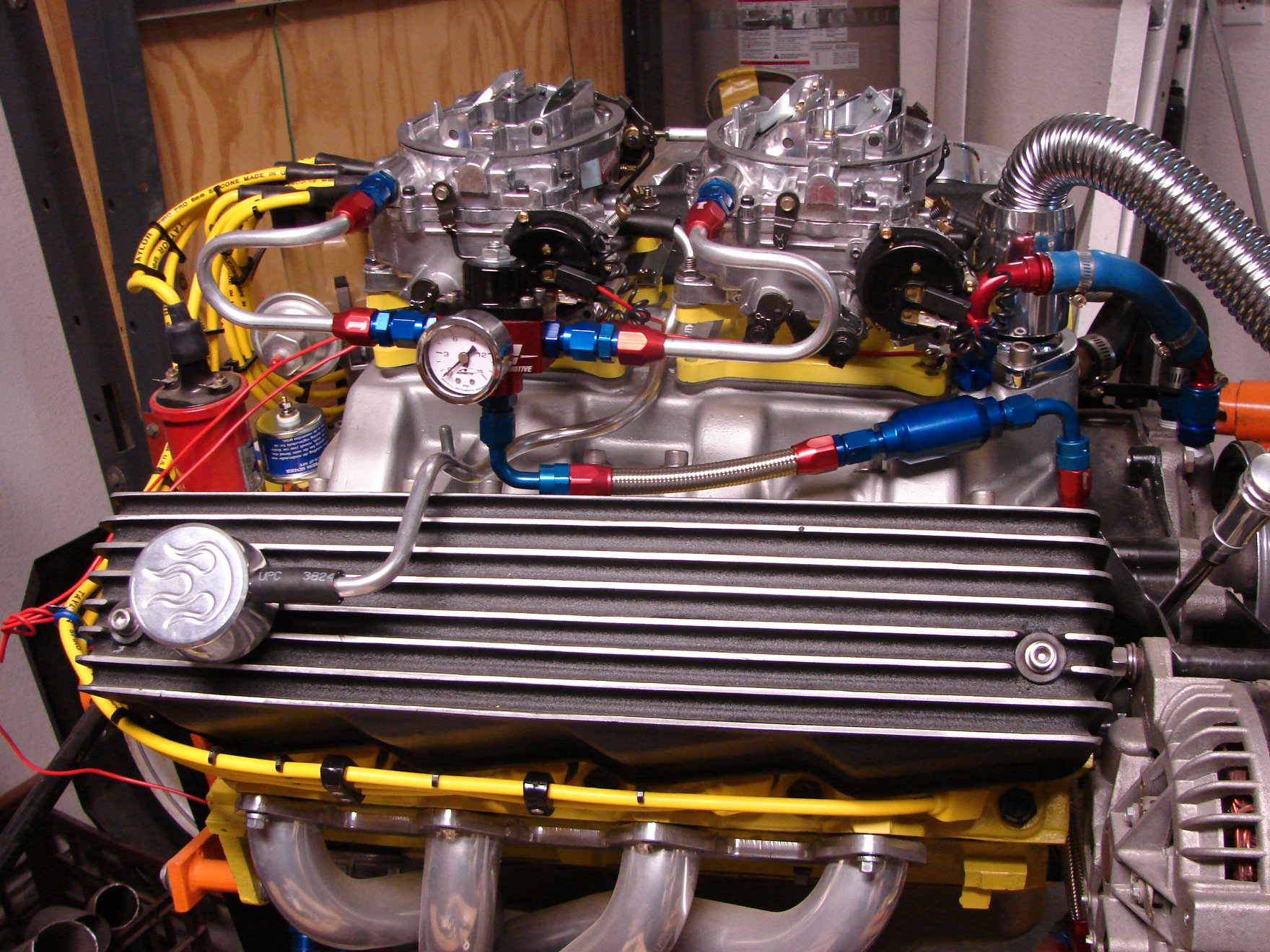

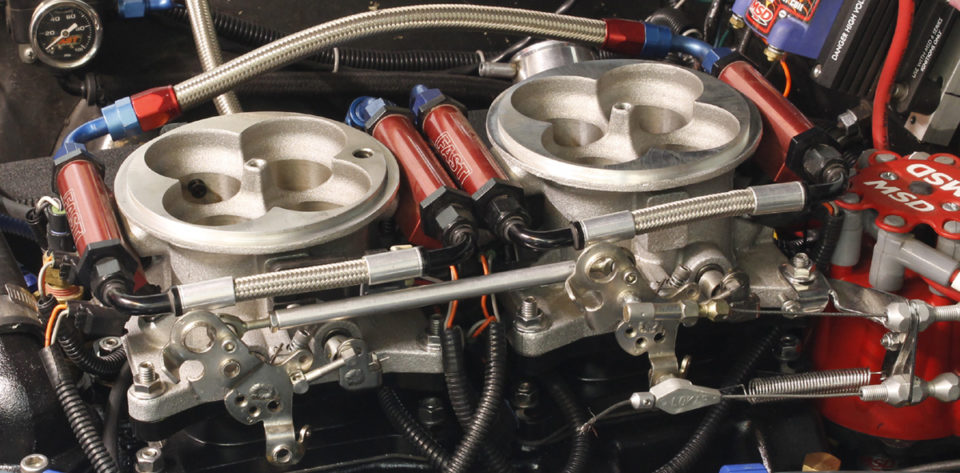

Dual quads always command attention at a car show, but the fuel they use can suck a wallet dry.

Dual quads always command attention at a car show, but the fuel they use can suck a wallet dry.

Most carburetors are tuned for a specific application in pretty optimal conditions. What that means is that they were built with the jets and metering rods that were needed for a specific application – just not your specific application. There’s a formula for determining the proper CFM for a specific engine displacement, and despite what our butt-dynos tell us, dropping a 750 Double-Pumper on our Aunt’s hand-me-down Nova with it’s anemic 192 horsepower small-block isn’t going to make your car run better or faster.

Carburetors, despite the claim, still should be tuned to your specific engine at a shop that is capable of testing the vehicle. Here in California, a well-known shop that can do just that is Westech Performance Group in Mira Loma. They’ll be the first to tell you that carburetors are really not “ready to run” right out of the box, and for them to perform at their best they should be dyno-tuned.

The car ran great, but fuel delivery was a problem: one 500 CFM carburetor wasn’t enough at low RPMs, and a pair of them was too much. The solution was a progressive linkage and a 625 CFM primary with a 525 CFM secondary carb. It actually worked very well.

The car ran great, but fuel delivery was a problem: one 500 CFM carburetor wasn’t enough at low RPMs, and a pair of them was too much. The solution was a progressive linkage and a 625 CFM primary with a 525 CFM secondary carb. It actually worked very well.

When you add up the cost of a new carburetor in the 500-750 CFM range, your cost is from $325 up to over $600. Add to that the cost of actually tuning your carburetor at a shop, which can run from $350 to $500, and you’re now getting close to the cost of some of the least expensive EFI systems on the market.

FiTech EFI systems are being marketed as a cost-effective replacement for the carburetor, with basic systems selling for the cost of a higher-priced carburetor – about $800. Of course, you would still need to work out the particulars with regards to a new fuel pump, filters, and fuel lines, but you get the gist of it. Then there’s the cost of fuel and what your MPG looks like, and that’s what we’ll get into next.

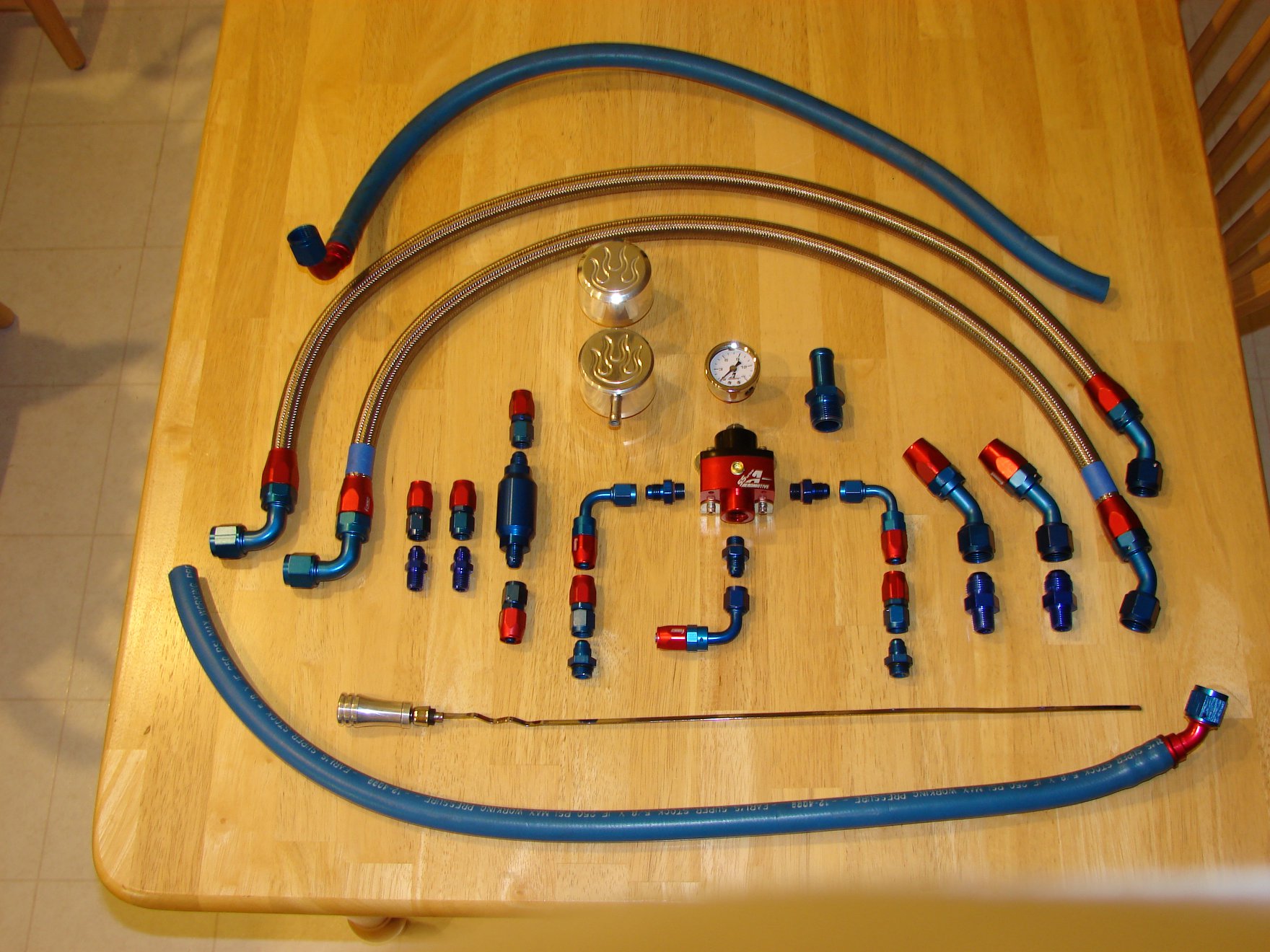

Even with a carburetor, the amount spent on fuel lines, anodized fittings, a fuel pressure regulator – these can all add up in a hurry.

Even with a carburetor, the amount spent on fuel lines, anodized fittings, a fuel pressure regulator – these can all add up in a hurry.

Going From Dual Quad To Dual Quad EFI

When the engine was built for our 1965 Plymouth Belvedere, the plan was for a dual quad system. It wasn’t a potent mill to begin with, but there was something about these 318 Polyhead Mopars with multiple carburetion that just looked right. It’s a unique engine that was not really designed for high horsepower, but it did come from the factory in the late 1950s with a pair of 390 CFM WCFBs (Will Carter Four Barrel).

The build consisted of ported and polished heads, a Weiand dual-quad intake made of unobtanium, and a set of headers from TTI Exhaust. The block was bored .060 over, and could take pistons all the way up to .120 over. But this engine is heavy, and it is often referred to as a boat anchor. It weighs in at 70 some odd pounds less than a Chrysler 440ci mill – with an extra 122 cubes.

Try to find this rare aluminum intake and you might expect to pay upwards of $1,000 in decent condition. Those TTI headers were a welcome performance part, prior headers for this engine were somewhat lame – or non-existent.

Try to find this rare aluminum intake and you might expect to pay upwards of $1,000 in decent condition. Those TTI headers were a welcome performance part, prior headers for this engine were somewhat lame – or non-existent.

Still, the Poly 318 was unique enough to keep under the hood, and while a pair of 500 CFM carburetors was the original plan, a mismatched set of Carter AFBs running on a progressive linkage was the best performer – regardless of what the internet experts said. Still, nine miles per gallon was not great, and it was time to figure out a better way to go, and that came in the form of a FAST dual quad EFI system.

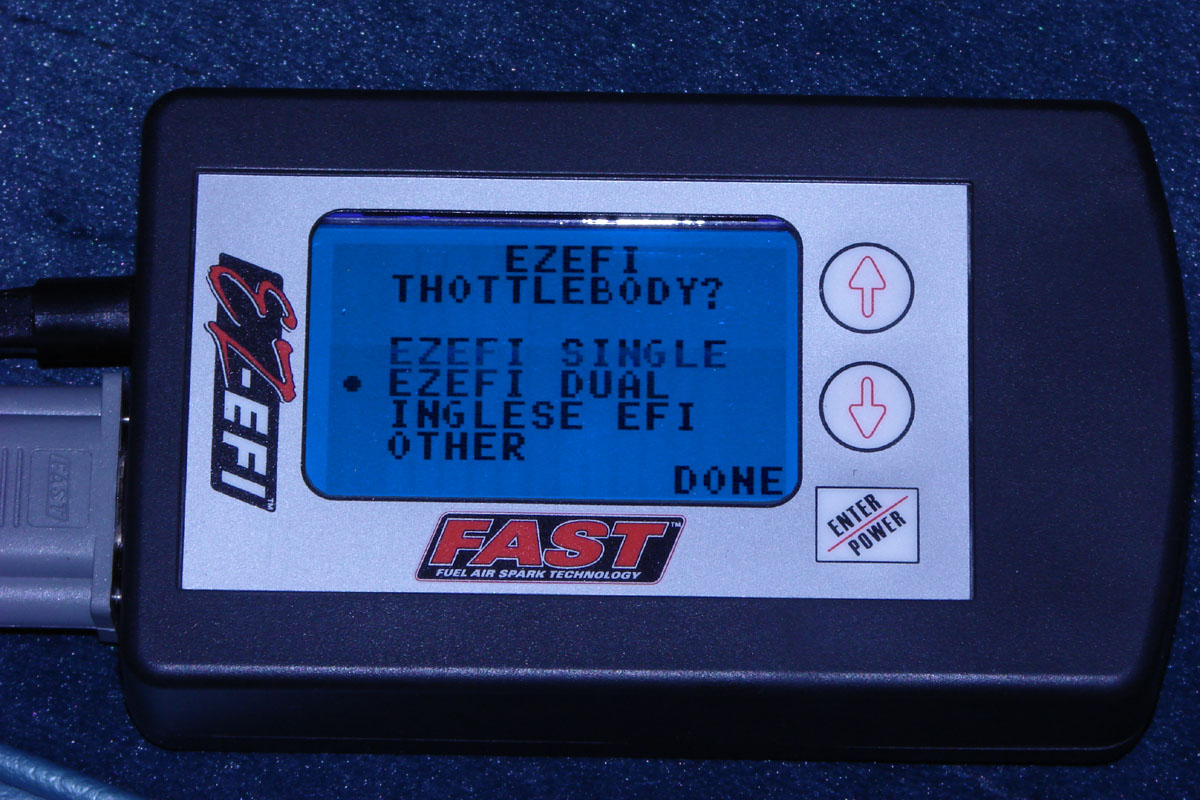

While EFI systems have become much easier to install, you might think that installing a dual quad system raises the bar of difficulty exponentially. However, that’s not the case with our install. The components and the wiring harness is usually enough to scare most people off, but there’s really not much to it since the only requirements are bolting on the kit, connecting the harness, and making selections on the handheld controller.

The early handheld was a bit archaic and clunky to use, the full-color upgrade actually made it more fun to use and had far more features.

The early handheld was a bit archaic and clunky to use, the full-color upgrade actually made it more fun to use and had far more features.

Instead of mounting a pair of carburetors, you mount a pair of throttle bodies on your dual quad intake. The second throttle body was simply a bare unit with four fuel injectors, as the main throttle body contained the important sensors, such as TPS, CAI, etc. A set of jumper harnesses connected the four additional fuel injectors to the main throttle body, and the selection of “Dual Quad” on the handheld took care of the rest.

EFI Fuel System

Early EFI conversions were advertised as not needing a fuel return system, but as many of us have learned it is probably best to provide a return system to the fuel tank. It will eliminate a lot of potential problems, and give you peace of mind as well. EFI systems require a much higher fuel pressure than a carburetor, but the flow rate isn’t drastically changed. The pressure is to ‘squirt’ the fuel into the intake in pulses, either timed with the ignition or the EFI brain box. It sort of becomes an electronic accelerator pump, for lack of a better explanation.

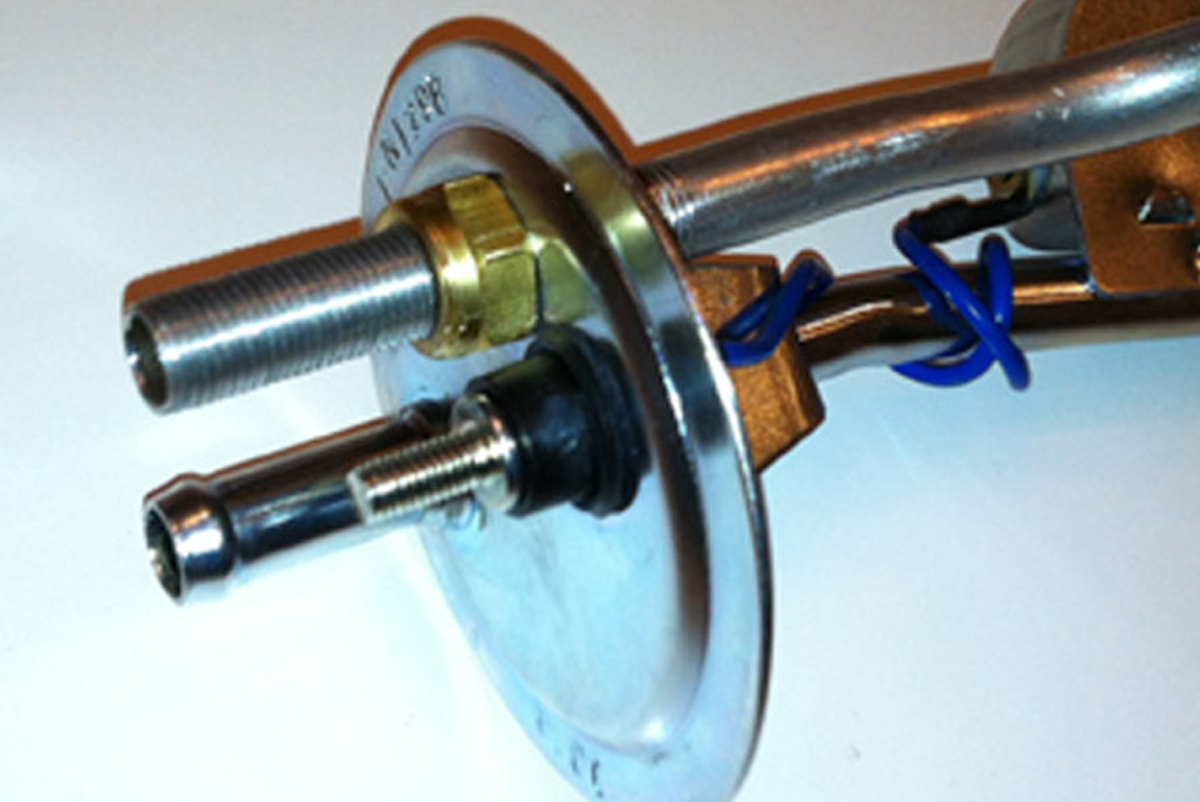

Most carburetor applications have an external pump – either mechanical on the block, or a frame-mounted electric inline. You can install an inline pump for EFI, but the best choice is to install an in-tank pump, which can be another expense. There are retrofit kits from companies like Aeromotive that allow you to install an EFI pump system into your stock fuel tank with some careful cutting, but it does require a complete clean and flush of your fuel tank to remove the fumes that could cause a dangerous explosion.

Initially, we setup our OE fuel sender with a return line, but later decided a new fuel tank from Rick’s Tanks was going to be the best setup.

Initially, we setup our OE fuel sender with a return line, but later decided a new fuel tank from Rick’s Tanks was going to be the best setup.

Another option is to have an aftermarket fuel tank, like the one we installed from Rick’s Tanks, in El Paso, Texas, which is another high-dollar expense to add to your EFI conversion. Replacement tanks can be bought for a couple hundred bucks, while a custom, stainless steel tank can be as much as $1,400.

When you start adding this up, you’re now likely climbing back on that fence because the cost of converting to EFI is much more than just buying a basic unit. You could be into a couple thousand bucks when all is said and done, but that is how to do it properly. It’s all relevant, because when you think about that carburetor you purchased for $400, to install it properly required a tune-up kit and dyno-tuning, so there’s also an added expense, albeit far less than the added expenses of an EFI conversion.

At this point, the Plymouth was only used for cruising, car shows, and occasionally to and from work, but it got a lot of miles on it and the EFI system made a difference at the pumps.

At this point, the Plymouth was only used for cruising, car shows, and occasionally to and from work, but it got a lot of miles on it and the EFI system made a difference at the pumps.

Is 4 MPG Worth It?

This doesn’t start to look like an EFI system will pay for itself unless you take into account that it might start doing so several years after you installed it. But then there are the benefits that sometimes help outweigh the additional costs. Fuel mileage can increase considerably, and our FAST dual quad system bumped our MPGs from the nine we were getting with carburetors up to about 13 with the EFI system.

Adding to the better fuel economy, your engine will start better, idle smoother, and will automatically self-tune while you’re driving the vehicle. Perhaps you can start to see that while the costs aren’t exactly comparable, the benefits of an EFI system are much better. Anyone who has driven up over the Grapevine with a carburetted vehicle here in Southern California will attest to how poorly a vehicle will run when faced with a changing altitude.

Sure, a pair of carburetors looks cool on almost any hot rod or musclecar, but if you drive it a lot, you might want to think about EFI.

Sure, a pair of carburetors looks cool on almost any hot rod or musclecar, but if you drive it a lot, you might want to think about EFI.

If you drive your car a lot and add it up over several years, you might be closer to seeing how an EFI conversion will pay for itself over time. The wideband O2 sensor that tells the EFI computer whether you need more fuel or not will continue to make adjustments no matter where you drive or what the conditions are. The computer will keep ‘learning’ and making adjustments, much like you would if you had your carburetor dyno-tuned every time the car didn’t perform at its peak.

Then there’s another perk that most manufacturers don’t want you to expect, but it’s one I’ve seen every time we converted from carburetor to EFI: better power – sometimes as much as a 20 horsepower increase at the rear wheels. But why won’t the manufacturers tell you that? It’s simple, actually, because it really depends on what you’ve done with your carburetor.

It looks like a lot to deal with, but they tune themselves, so once you’ve set up the system, you really don’t need to mess with it anymore.

It looks like a lot to deal with, but they tune themselves, so once you’ve set up the system, you really don’t need to mess with it anymore.

Remember the ‘ready to run’ comment? Well, if that’s all you did was install your carburetor and you neglected to have it dyno-tuned, then you’re probably not getting the most potential from your carb. That’s where EFI conversions can provide an increase in power: they show that tuning works and can not only make your vehicle more fuel efficient, but it can also utilize the power more efficiently.

We have a lot into our Plymouth, but when you think about it you probably spent several grand on your engine, another few thousand or more on the paint, then the interior was probably a couple thousand as well. Wheels and tires to make it look better can be a couple thousand bucks, too. So when you think about how much you put into the looks of your car, plus the performance factor of a fresh build with a handful of go-fast goodies installed, an EFI conversion is just another cog in the system of hot rodding that makes sense. It did for the Plymouth!

Sure, under a pair of K&N filters it’s hard to tell from a few feet away that it’s an EFI system, but it’s worth it when you add up the number of trips to a gas pump.

Sure, under a pair of K&N filters it’s hard to tell from a few feet away that it’s an EFI system, but it’s worth it when you add up the number of trips to a gas pump.